The Technology: How it Works

See Hydro-Jex® in action

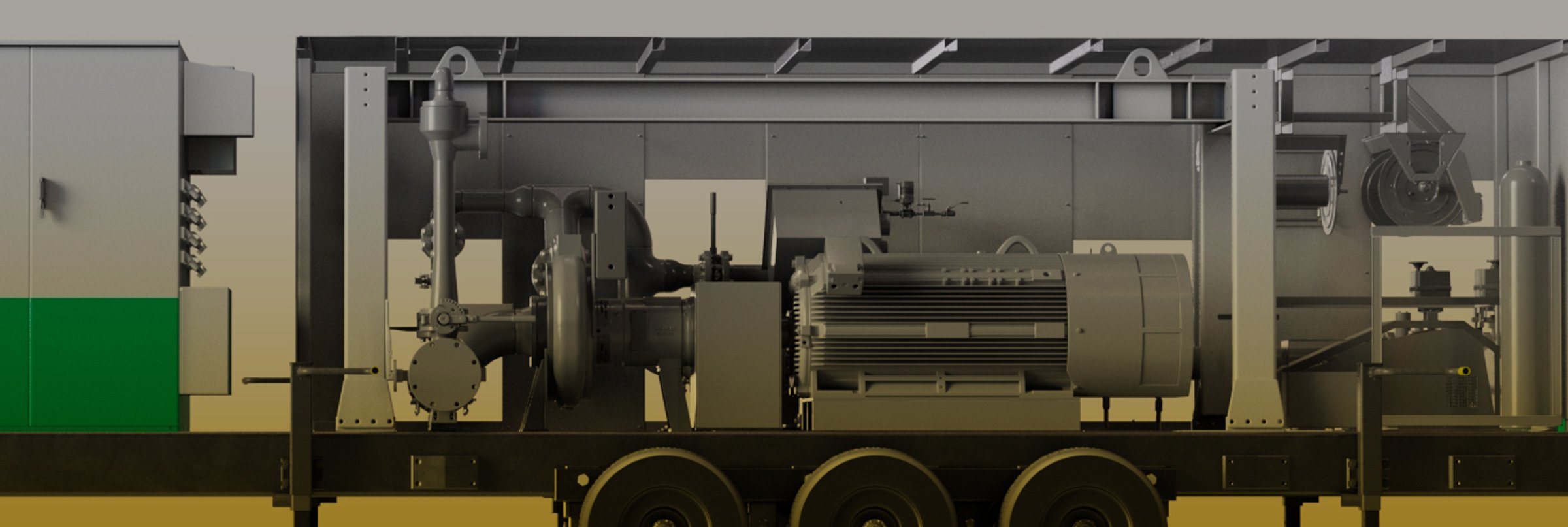

Hydro-Jex® is a broadly patented and proprietary set of hardware, software, trade secrets, chemistry and implementation procedures designed to help gold, silver and copper heaps operate more effectively, safely and sustainably.

It consists of a patented methodology (and related trade secrets) that penetrates dry zones and targets trapped solutions in heap leach piles and low-grade materials through the application of tailored, pressured injections and a sequence of controlled rinses.

A patented process for additional metal recovery

Hydro-Jex® is the only advanced injection technology available for copper and gold heap leaching. The propriety process maximizes and accelerates metal recovery while providing enhanced heap stabilization and a dramatically reduced environmental footprint.

REVOLUTIONARY

Without Hydro-Jex®

Leaching fluid forms channels along the paths of least resistance

Substantial amounts of clandestine metal are trapped in “dry zones” of the pad

Pockets of trapped solution form when clay and other materials create impermeable barriers, destabilizing the heap

“Sour zones” in the heap lower the pH of the wetting solution (in the case of gold leaching) or consume acid (in the case of copper leaching), inhibiting metal recovery

A significant percentage of metals in the heap are written off as unrecoverable

With Hydro-Jex®

Leaching fluid is spread evenly through the pad using tailored pressure horizontal injection

Dry zones are eliminated, enabling fluid to reach more of the metal in the pad

The pressure injection disrupts and releases pockets of trapped solution for enhanced heap stability and metal recovery

The process also corrects the negative effects of sour zones

As a result, metal from up to billions of additional tons of material can be recovered

The Hydro-Jex® Process

-

Heap pads can contain millions of tons of copper or gold ores.

-

Placement is based on metallurgical data for optimal stability and metal recovery.

-

This creates thousands of injection points inside the heap.

-

The Hydro-Jex® system is capable of injecting 10-15 times more solution per hour than conventional surface irrigation and spreads the solution evenly throughout the material being injected, creating horizontal pathways.

-

Fluids flow into a recovery pond for collection and processing.

-

With Hydro-Jex®, mining companies can claim significantly more metal than is possible with conventional irrigation methods.

-

This minimizes chemical usage and environmental impact.

When all metal is recovered, cleaning solutions can be injected to neutralize the remaining chemicals and stabilize the pad.

Want to know more?

Contact us to talk to our technical experts.